Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

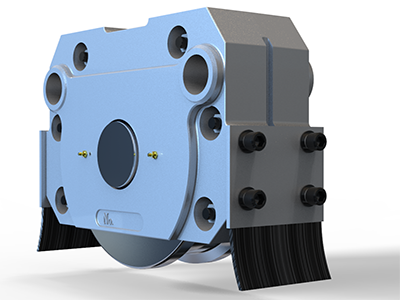

The DRS-200-NA-A-65-K-X-X travel wheel system is one of the core products in the DRS series of Demag, Germany. It is designed for high-load industrial scenarios and is widely used in port cranes, heavy handling equipment, and automated warehousing systems. Its model naming and structural design both reflect the characteristics of modularity and high adaptability. The following is an explanation from four aspects: model analysis, technical parameters, structural advantages, and scope of application.

Model analysis

DRS: Abbreviation for Demag Rail System, identifies the product series.

200: Wheel diameter (in millimeters), indicating that the wheel diameter of this wheel system is 200mm.

NA: Wheel type identification, NA stands for "Non-Driven" wheelset.

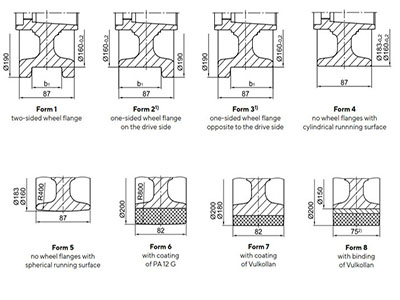

A: Wheel design type, A stands for "double flange wheel" (with guide flanges on both sides), suitable for double-sided limit scenarios of the track.

65: Wheel width (in millimeters), 65mm, is used here to ensure the contact area with the track and load stability.

K: Connection code, K stands for "Top Connection", which can be directly fixed to the equipment steel structure by bolts

X: No guide rollers

X: No gearbox considered

Technical parameters and performance

The core technical parameters of DRS-200-NA-A-65-K-X-X are as follows:

Maximum load:

10 tons per wheel group (corresponding to DRS-M 200 model), suitable for heavy equipment;

Wheel group material:

Travel wheel: ductile iron (GGG 70), stainless steel, polyurethane, or 42CrMo alloy steel, both wear-resistant and impact-resistant; wheel type and material can be customized according to your environment.

Wheel group shell: aluminum alloy or high-strength cast steel. Aluminum alloy is lightweight and corrosion-resistant; a high-strength cast steel or cast iron shell can avoid strong external impact and collision.

Dimensions and weight:

Wheel diameter 200mm, wheel width 65mm;

Overall dimensions 340mm×65mm×238mm (length×width×height);

Single group weight is about 35.7kg (standard configuration); can withstand a maximum load of 10t.

Adaptable track:

It matches V-type, single flange, double flange, flangeless track, maximum track width 101mm;

Protection level:

IP65, suitable for humid and dusty environments.

Structural design advantages

The modular design of DRS-200-NA-A-65-K-X-X gives it multiple technical advantages:

High rigidity support

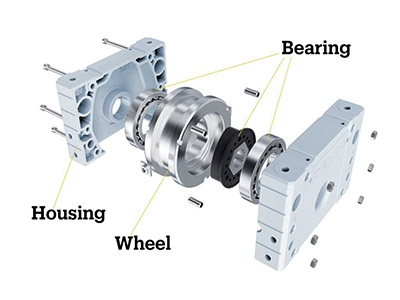

The shell adopts a five-sided closed casting design to fully protect the travel wheels and bearings and reduce external impact damage.

Pre-lubricated deep groove ball bearings (DRS-M series) or tapered roller bearings (DRS series) are configured internally to ensure long-term maintenance-free operation.

Flexible adaptability

Provides 4 connection methods (top, end, side, pin), which can be seamlessly integrated into the customer's steel structure.

Reserved threaded holes support the rapid installation of guide rollers, track cleaners, and other accessories.

Accurate positioning and convenient maintenance

Laser alignment system (DRS series) or fixed alignment design (DRS-M series) simplifies the installation and calibration of multi-wheel units.

Split housing design, no need to dismantle the whole structure to replace the travel wheel, reducing downtime.

Intelligent wear monitoring

Integrated mechanical wear indicator, intuitively displays the wear status of the wheel rim through a color scale, and supports remote diagnosis.

DRS-200-NA-A-65-K-X-X, as a representative of Demag's modular drive system, has become the preferred solution in the heavy industry field with its high load capacity, flexible configuration, and intelligent operation and maintenance characteristics. Its design fully reflects the balance between standardization and customization, which can significantly improve the operating efficiency of equipment and reduce the cost of the entire life cycle.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.