Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

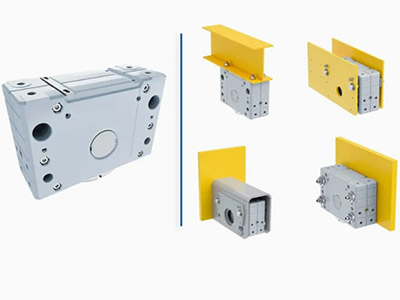

The DRS-160-A45-D-65-K-X-A30 Demag wheel is a material handling travel unit of the Demag DRS-M series. The travel wheel block of the DRS series is suitable for double rims, single rims, no rims, polyurethane wheel hoops, or specific V-shaped tracks. The components are precise, the operation is smooth, and the load-bearing capacity is strong. The following introduces the technical parameters, advantages, and applicable scenarios of DRS wheels.

Technical parameters of DRS-160-A45-D-65-K-X-A30

A45: Driven wheel block, for torque bracket fitting and indication of hub profiles

D: GJS(GGG) with flange on one side

65:Travel wheel tread

K: Top connection

X: Indicates no guide rollers

A 30: Offset gearboxes

Load bearing: 7t

Weight: 18.3kg

Advantages of DRS travel wheel block

• 8 models (such as DRS-M 112 to DRS 500), with a single wheel load covering 2.75 tons to 40 tons, meeting the needs of light warehousing to heavy metallurgy.

• Modular components support quick replacement of travel wheels, connectors, and accessories (such as guide cleaning systems, buffers)

• The travel wheels are made of ductile iron (GGG 70), which has both self-lubricating properties and wear resistance, a low friction coefficient, and life extended by more than 30%.

• The box adopts a five-sided closed casting structure with lifetime lubricated bearings to effectively resist harsh environmental influences such as dust and high temperature.

• Connection methods include top (K type), pin (B type), end (S type), and side (W type), which are compatible with installation environments such as steel structures and hollow beams, and have strong scalability.

• Customized solutions can be made according to track type and load requirements, significantly reducing procurement and maintenance costs.

Typical application scenarios of DRS wheel blocks

Industrial cranes and material handling systems

For the travel mechanism of bridge cranes and gantry cranes, their high-rigidity box and torsion-resistant bracket design can withstand frequent start-stop and impact loads. For example, the DRS 160-MA35-B flangeless wheel block with side guide wheels is suitable for rail transportation in high-temperature environments in metallurgical workshops.

Intelligent logistics warehousing system

In automated warehouses, the DRS160 model is compatible with AGV trolleys, stackers, and other equipment with its compact design (height 187mm) and high ground clearance to ensure efficient flow of goods. Its polyurethane wheel hoop version (such as DRS160-F) can also achieve low-noise operation, suitable for clean workshop needs.

Heavy industry and special environments

• High-temperature workshop: The DRS wheel block with high-temperature resistant materials and sealed bearings can operate stably in steel smelting and casting workshops.

• Dust environment: The closed box structure prevents dust intrusion, and the hardened tread wheel type (optional accessory) extends the service life.

• Railway transportation and port machinery: Large-diameter models (such as DRS 500, with a load capacity of 40 tons) are suitable for port gantry cranes and railway freight yard handling equipment. Its high torque compatibility can be seamlessly integrated with Demag modular reduction motors to improve drive efficiency.

Whether it is the precise needs of smart logistics or the extreme working conditions of heavy industry, the DRS series can enable enterprise productivity upgrades with high adaptability and low maintenance costs. Contact SHIYANG for relevant detailed quotes.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.