Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

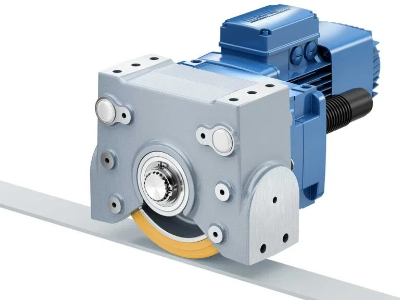

The DRS 250 A65-C-75-B-X-A50 polyamide flangeless wheel represents a solution designed specifically for applications that require medium-weight construction, corrosion resistance, and adaptability to high-load environments. In industrial material handling, conveyor systems, and automated machinery, DRS wheels play a vital role in ensuring smooth movement, load-bearing stability, and long-term durability. Below are the technical specifications of this model, the unique advantages of polyamide (nylon) construction combined with a flangeless design.

Specific parameter analysis

DRS: Demag wheel block track travel wheel identification

250: Wheel diameter 250mm

A65: Drive wheel block for torque bracket installation and hub profile indication

C: Flangeless polyamide, larger diameter

75: Travel wheel tread

B: Pin connection

X: No guide wheel

A50: Offset gearbox

Weight: 62kg

Carrying capacity: 16t

Technical advantages of polyamide structure

Polyamide (nylon) wheels are known for their versatility in harsh environments. The DRS 250 model precisely utilizes these characteristics:

• High mechanical strength and durability

Load distribution: The inherent tensile strength of polyamide (up to 80 MPa) ensures uniform load distribution, reducing stress on shafts and bearings.

Impact resistance: Absorbs impacts from uneven surfaces to minimize damage to transported goods or equipment.

• Corrosion and chemical resistance

Saltwater/acid resistance: Unlike metal wheels, polyamide resists rust and degradation caused by chemicals, making it ideal for food processing, marine, or pharmaceutical environments.

Non-conductive: Safe for use in environments with electrical hazards.

• Low friction and noise reduction

Self-lubricating properties: Reduces friction with the track or floor, reducing energy consumption in automated systems.

Quiet operation: Ideal for noise-sensitive areas such as warehouses or laboratories.

• Lightweight design

Weight reduction: Polyamide wheels are 60-70% lighter than equivalent steel wheels, making installation easier and reducing inertia in high-speed applications.

• Flangeless design: Functional benefits

This model has no flanges (side flanges), which offers clear advantages in specific scenarios:

• Enhanced lateral flexibility

Lateral movement: Flangeless wheels allow lateral movement on tracks or rails to accommodate misalignments in conveying systems.

Space efficiency: Eliminates the risk of flange interference in tight spaces, such as curved conveyor sections.

• Simplified maintenance

Debris Removal: Open sides prevent dust or debris from building up, reducing wear and maintenance frequency.

Easy to replace: Flangeless designs typically feature bolt-on hubs for quick installation.

• Customizable navigation systems

Compatibility: Works with external guides or sensors for precise steering in AGVs (Automated Guided Vehicles).

Application scenarios

The DRS 250 A65-C-75-B-X-A50 excels in demanding environments:

Automotive: Conveyors transporting heavy engine parts.

Food & beverage: Hygienic, washable wheels for production lines.

Logistics: AGVs in warehouses that require quiet, low-maintenance operation.

Mining/construction: Corrosion-resistant wheels for outdoor material handling.

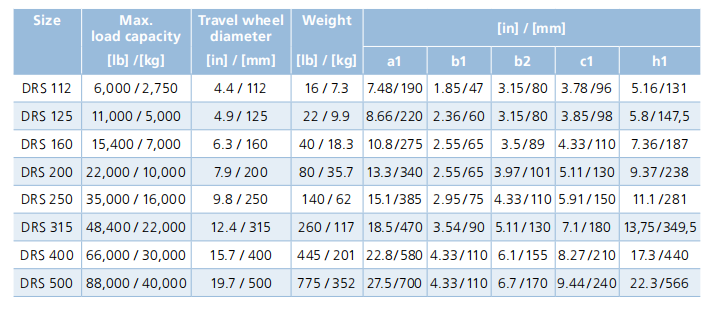

The DRS 250 A65-C-75-B-X-A50 flangeless polyamide wheel embodies the fusion of advanced polymer engineering and practical design. Its flangeless configuration, coupled with the elasticity of polyamide, makes it a versatile choice for industries that prioritize efficiency, durability, and adaptability. And using its unique characteristics, Shiyang engineers can provide customization of the wheel system of DRS 112-DRS 500 by understanding parameters such as load, track, cleanliness, etc. According to the size and material of the wheel, optimize system performance and select accessories to reduce life cycle costs.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.