Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

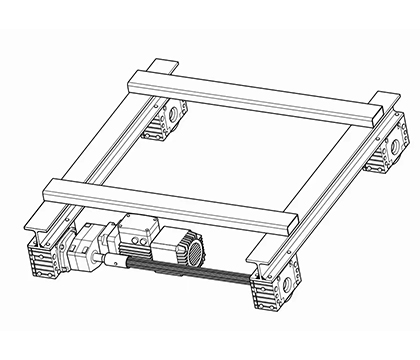

An end beam is a crucial structural component often used in overhead cranes, gantry cranes, stacker cranes, and transfer carts. It acts as a horizontal support beam located at the ends of the equipment's framework.

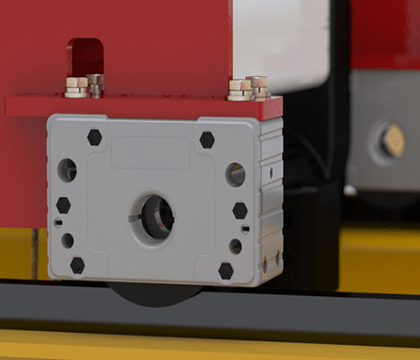

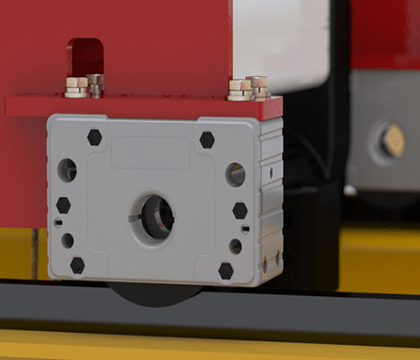

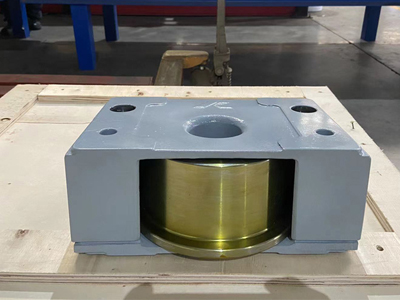

Modular wheel block system for crane end beams

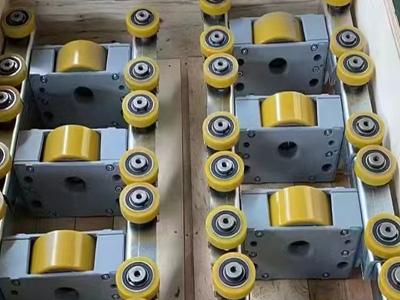

DRS modular wheel block system is a rail-mounted crane component that comprises a set of wheels and a frame to support the load during movement. The system can handle loads up to 40 tons, and the wheels can have a diameter of up to 500 mm.

DRS modular wheel block can be used in various cranes, including gantry cranes, bridge cranes, etc. Its reliable power transmission and stable traveling performance enable the crane to operate efficiently under various working conditions.

DRS Wheel Blocks System offers a versatile, compact wheel block with simple and flexible characteristics for excellent performance. The system is suitable for use in stacking cranes, shield machines, equipment support, metallurgical trolleys, and other industries. It boasts simple installation and maintenance, good starting and braking performance, track-friendly design, and comes equipped with a laser calibration system to eliminate installation errors. The wheel surface can be specially hardened to meet high-speed operation requirements. The wheel block is durable, effectively protecting the travel wheel and bearings layout, and provides good ground clearance.

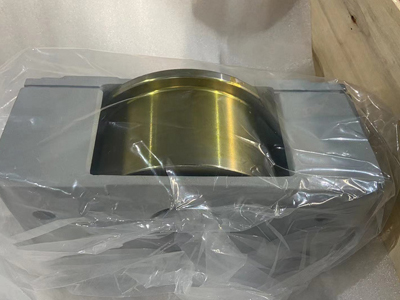

Crane Wheel Block assembly with the continuous development of crane structure. Crane wheels are now smaller in diameter and come in various assembly forms. For instance, geared crane wheel assemblies typically include axles, wheels, bearings, and gear rings. They are suitable for single-beam cranes, small-tonnage double-beam crane hoisting mechanisms, and single-beam gantry cranes under 10 tons. This type of assembly has a simple structure, is cost-effective, and has highly interchangeable components, making it easy to purchase. However, it is not very convenient to adjust when the crane wheel is gnawing or derailing, and replacing or removing the crane wheel is relatively cumbersome.

Modular wheel blocks are typically made of high-quality steel, such as forged or cast steel, known for their durability and ability to withstand wear. The crane wheels undergo heat treatment processes, like quenching and tempering, to enhance their hardness, strength, and resistance to wear and fatigue. Some crane wheels use self-lubricating materials, while others need regular application of lubricants to reduce friction, wear, and heat generation at the wheel and rail interface.

Our experts are ready to help you identify the most suitable crane Modular Wheel Block System to meet your specific requirements and ensure the smooth and safe material handling processes. Contact us today to learn more about our innovative DRS Wheel Block System offerings and how we can help take your crane operations to new heights.

Transfer carts DRS traveling wheel block is responsible for supporting and driving the transfer cart to move smoothly. It can be customized according to actual needs to meet different transportation requirements.

The wheel blocking system is a pivotal component in modern material handling solutions, designed to enhance the efficiency of various industrial applications.

DRS wheel block system is a versatile travel wheel system for heavy-load handling applications.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.