Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

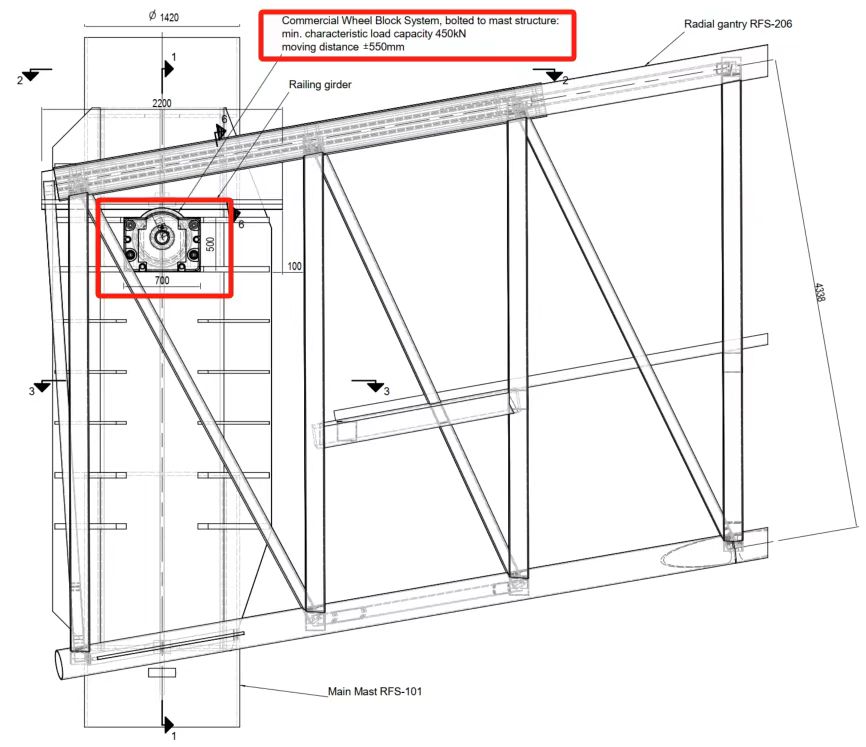

Commercial support wheel systems, also known as Demag travel wheel systems, are designed to provide unparalleled performance as support components in steel beam applications such as large shopping malls, stadiums, etc. These systems are designed for integration into steel structures and industrial equipment, combining modular flexibility, extreme durability, and sophisticated engineering design. This article explores the technical advantages of commercial Demag wheels as structural support wheels and their application in other industries.

Main advantages of Demag wheels as support wheels

Excellent load capacity and rigidity

Demag wheels can withstand extreme static and dynamic loads. For example:

• DRS-M series: each wheel can bear up to 10 tons.

• DRS series: With a load capacity of up to 40 tonnes per wheel, it is also ideal for moving overhead cranes and hydraulic presses.

• Robust housing materials - ductile iron, stainless steel, or polyamide wheels - ensure structural integrity even under long-term stress.

Modular design for custom integration

Demag’s modular system simplifies adaptation to a wide range of steel structures and equipment:

• Connection options: Top, side, pin, and end connections for seamless connection to beams, hollow sections, or custom superstructures.

• Prefabricated accessories: Threaded holes allow for direct integration of guide wheels, track sweepers, or buffers without modification.

• Custom hub profiles: Options include flanged hubs for track guidance, concave hubs for round track, and Hydropur or polyurethane tires for noise reduction.

Enhanced durability in harsh environments

• Corrosion resistance: Stainless steel models resist corrosion in open-air environments.

• Low-maintenance bearings: Sealed, lifetime lubricated bearings and self-lubricating hub materials such as GGG 70 cast iron minimize wear and downtime.

Simplified installation and alignment

• Fixed alignment technology: DRS-M hubs feature pre-centered bearing seats, eliminating the need for time-consuming adjustments during changeovers.

• Plug-and-play design: pre-assembled units with standardized sizes reduce the complexity of installation in steel frames.

Cost-effective long-term performance

• Extended service life: Demag wheels have a service life 2-3 times longer than conventional rubber wheels due to their hard-wearing polyurethane, cast iron, or stainless steel materials.

• Reduced maintenance: the enclosed housing protects the internal components from debris, while modular upgrades (e.g., replacing polyamide wheels with Hydropur tires) increase adaptability.

Other applications of Demag support wheels

Steel structure support systems

• Bridge and gantry cranes: DRS wheel sets stabilize the end beams so that they pass smoothly over the track with loads of up to 40 tons.

• Building roof structures: RS series wheels support dynamic loads in retractable domes or movable stadium roofs and make full use of their high temperature resistance.

Heavy machinery and special equipment

• Hydraulic presses: DRS wheels provide stable support for heavy platens in stamping operations.

• Mining and construction vehicles: RS series wheels withstand abrasive environments and uneven terrain in ore transporters or concrete mixer trucks.

Demag wheel block systems redefine structural support with their unmatched load capacity, ease of installation, and durability. From stabilizing the steel frames of sports stadiums to ensuring precision in automated factories, these wheels are essential in the modern industrial ecosystem. Their modular design and low life cycle costs further consolidate Demag Wheels' leading position in heavy-duty solutions. For custom configurations or technical specifications, Shiyang can provide CAD drawings based on or to optimize integration.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.