Demag DRS wheel blocks is newly developed based on crane wheel technology innovation. The DRS wheel blocks can be used widely, which is easy to install, saving troubles during maintenance. Innovations cannot be stopped. Shiyang DRS wheel range systems can be used in countless mobile devices and systems – as single components or as complete travel unit, which has demonstrated their high reliability and long service life in operation, lower maintenance, and cost-effective. Demag wheel blocks are applied to many equipment, including the stacker cranes, lifting platforms, transportation system, portal cranes, crane installations, storage and retrieve machine, architectural applications, conveying systems.

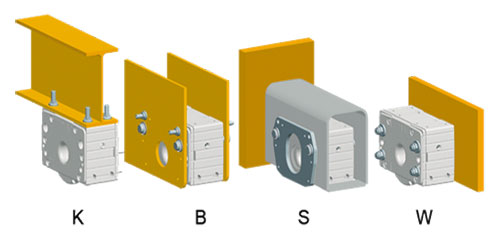

However, most of the time, these equipment has different installations and different connection methods enhance equipment applications by allowing for tailored solutions based on specific operational needs.

Top Connection: This type of connection features a wheel block mounted on top of a beam. It's commonly applied in overhead cranes and stacker cranes,where stability is crucial. The advantages include improved load stability and reduced sway during lifting operations, making it ideal for handling heavy loads safely and efficiently.

Pin Connection: In this configuration, Demag wheel block is attached using a pin through a designated hole. This method is often used in modular systems or portable conveyors. The primary advantage of pin connections is their quick assembly and disassembly, allowing for flexible configurations that adapt to changing operational needs.

End Connection: In this setup, DRS drive wheel block is connected at the end of a structure, frequently seen in industrial trolleys. The end connection enhances maneuverability, allowing for smooth transitions at the ends of tracks, which is beneficial for efficient operation in various logistical applications.

Side Connection: Here, DRS drive wheel block is attached to the side of a frame, commonly utilized in guided rail systems. This connection method offers easier access for maintenance and is particularly advantageous in tight spaces where maneuverability is limited, ensuring that equipment remains operational with minimal downtime.

The prepared mounting surfaces helped Demag wheel blocks applied in more equipment. It facilitate virtually any connection arrangement – ranging from top and end connection arrangements with bolted and welded connection elements, to side and pin connection arrangements for installation in hollow sections and cross beams. Top, end and pin connection arrangements make it possible to move and align the wheel blocks laterally even after they have been fitted.

Easy installation and alignment, compact sizes, and numerous connection options are essential features. Additionally, they incorporate various new elements that enhance user efficiency. The range consists of four sizes from 112 to 200, fully compatible with earlier models. Four additional wheel blocks (DRS 250 – 500) complete the DRS product line, offering load capacities of up to 40 tons.

Contact Shiyang to get Demag wheel blocks for your complicate connected equipment.